Energy is a priority for humanity, in that sense, green energies are a necessity to satisfy the energy shortage and preserve the environment. So electronic converters play a key role.

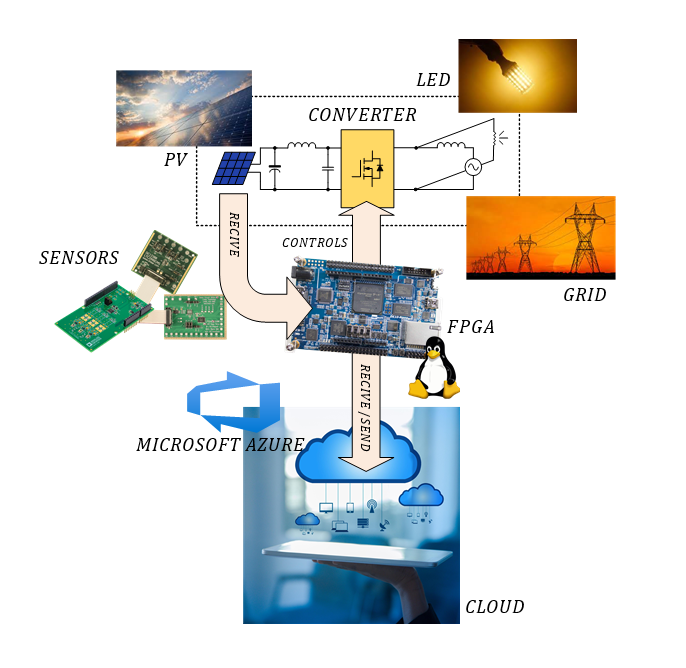

A converter management system connected to the cloud controlled by a FPGA is proposed for applications in industry 4.0. It has capabilities to integrate panels solar arrays (PVs), batteries, loads at the same time with different converters according to user requirements. That means that the proposed system manages modulation, algorithms, collect information, and distribute energy.

For example, if the user requires a PV, then the P&O MPPPT algorithm is implemented to obtain the maximum energy in the PVs.

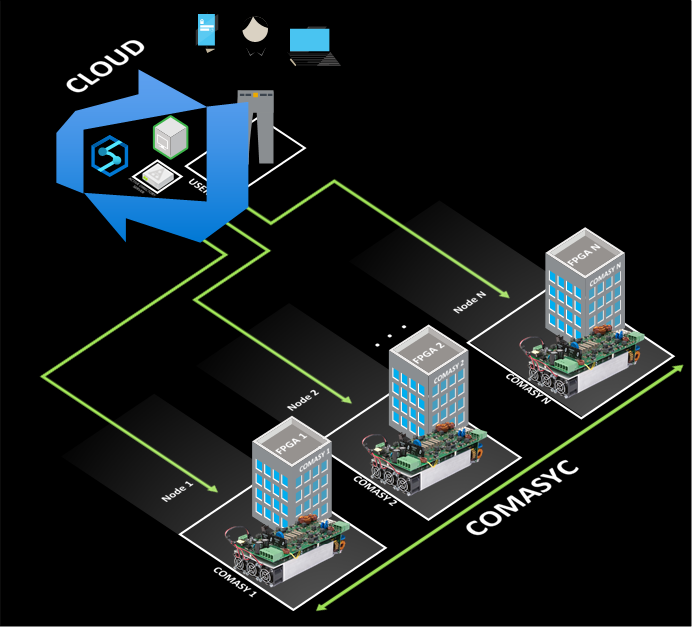

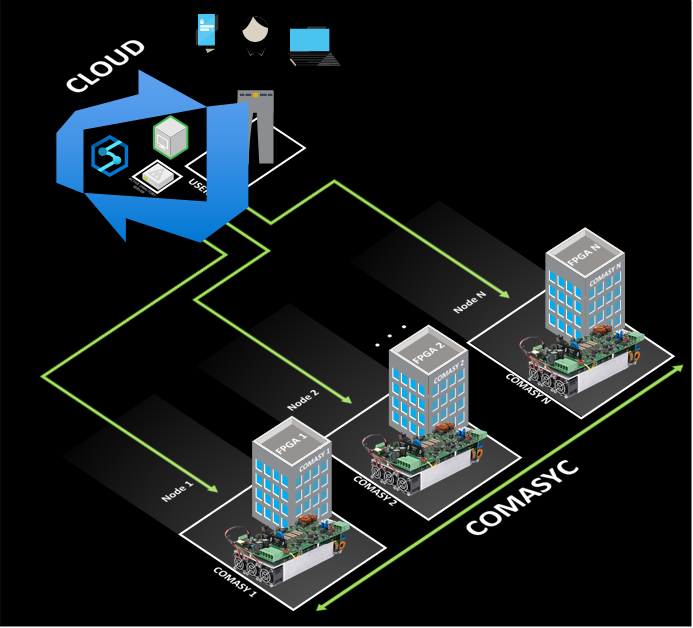

On the other hand, parameters such as energy consumption and production of each node are important for the redistribution of energy, for this reason, this model has a single brain that is connected to each node. So, a novel control is proposed based on load balancing managed by the cloud for high-priority requests. The cloud is the single brain that controls the system and organizes the flow power among nodes. The project is focused on the Peruvian reality for places where energy has to be a priority.

Demo Video

Project Proposal

1. High-level project introduction and performance expectation

1. JUSTIFICATION OF THE PROJECT:

This technology helps the development and study of efficient use of renewable energy sources since it provides a safe and flexible platform for the channeling of these variable energies (they depend on factors such as rain, sunny days, winds, and others) in constant DC voltage to be stored in battery banks or used directly by energy consumers, it also provides real-time information on important variables such as electrical voltage, current and generated power. These variables can be remotely monitored by users to verify or modify their operation.

In power equipment, errors are very costly, such as making equipment work when it is no longer required or having unwanted current and voltage values that would have to be corrected almost immediately, in addition, this could cause various consequences such as deterioration and shortening the lifetime of the equipment and unnecessary energy costs. The remote control and management of variables (current and voltage) in power equipment is a necessity to correct these errors that can occur, quickly and without the need to always be in the plant.

2. TARGET AND TARGETED USERS:

Contribute to sustainable development and friendly with the environment through our idea of creating a system capable of remotely managing various types of power converters (reconfigurable system) in different places for application in different types of industry such as mining, fishing, construction, etc.

3. FEASIBILITY AND VIABILITY OF THE PROJECT:

While the market offers a wide range of microcontrollers and microprocessors that have the ability to send data to the cloud like Arduino or PIC, these lack their ability to handle multiple PWM signals and multiple analog channels, as well as having the ability to speed up control and algorithms, which are essential in converters, although these devices allow us I2C, SPI, UART, CAN, USB and other communications, no adjustments or changes can be made to the already configured hardware.

For these types of applications, industries use mid- or high-end DSPs that are very expensive, however, these cannot be modified without being in physical contact with the equipment, so COMASYC is a solution to this problem, in addition, is cheaper and innovative, so allows remote configuration.

COMASYC is based on the DE10-nano SOC, since it is a SOC-type FPGA that allows mounting operating systems (Linux, Android, or Windows) which offers us a wide remote communication path, and the server to use will be Azure.

4. DESCRIPTION OF THE PROJECT:

The purpose of this project is to contribute to the growth of the country under this ideal, the introduction of this type of system is proposed in each home or in a particular way, first in a condominium in which energy is managed intelligently from the cloud and having the security and confidence in our data are correct.

In addition, the control is intended to serve multiple operating points for various types of power converters and be reconfigurable, which takes the technology to the next level (partial reconfiguration) to achieve this long-term objective. The goal of this project is to introduce new technologies that allow the development of the use of green energy in rural and residential homes efficiently, it should be noted from the literature that exists today, everything is connected to the grid, which increases the complexity of this project.

2. Block Diagram

Fig. 1. The proposed project for sustainable development and friendly with the environment.

Fig. 1. The proposed project for sustainable development and friendly with the environment.

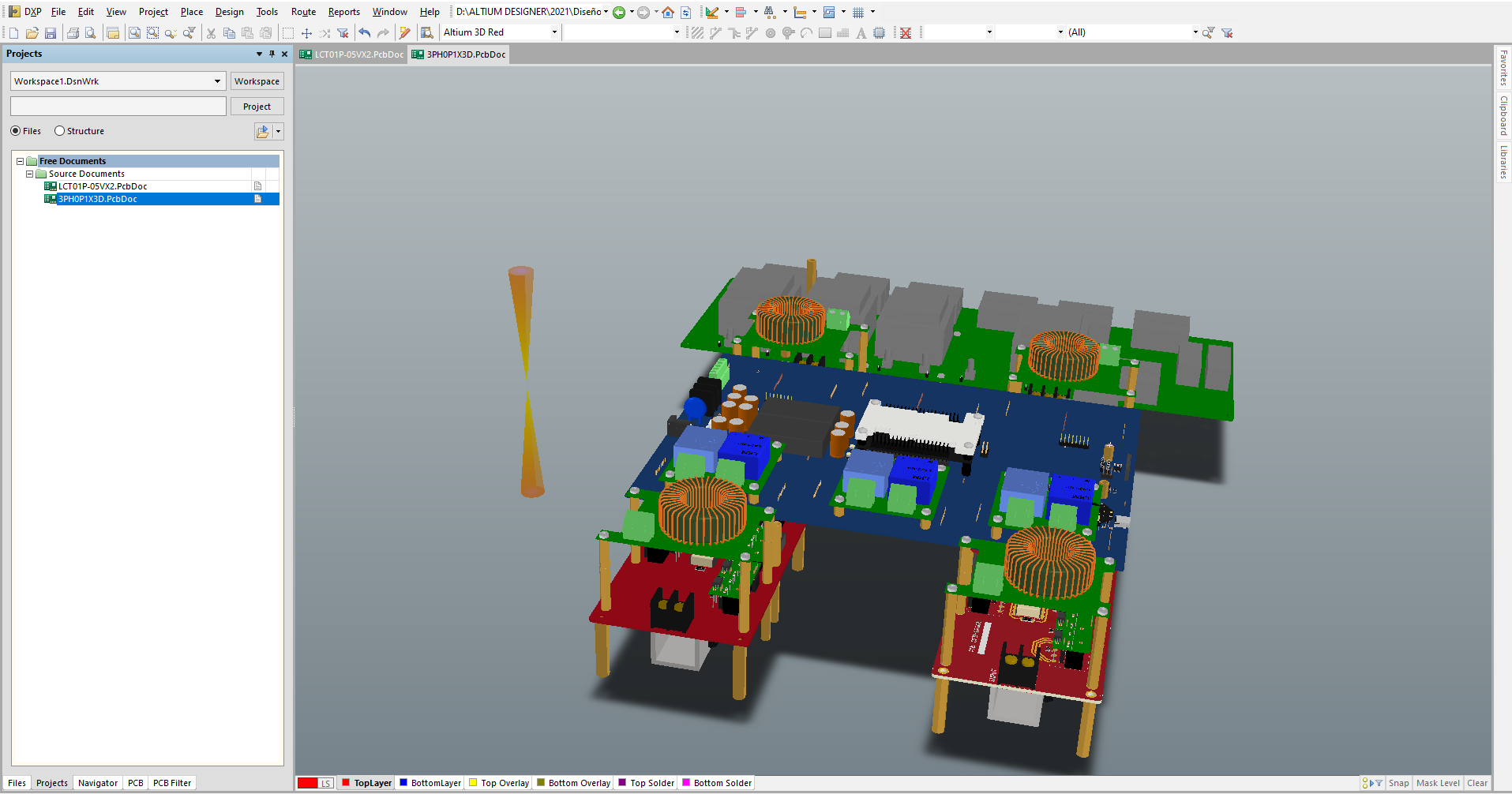

Fig. 2. Prototype technical information

Fig. 2. Prototype technical information

3. Expected sustainability results, projected resource savings

5. PROTOTYPE DESCRIPTION:

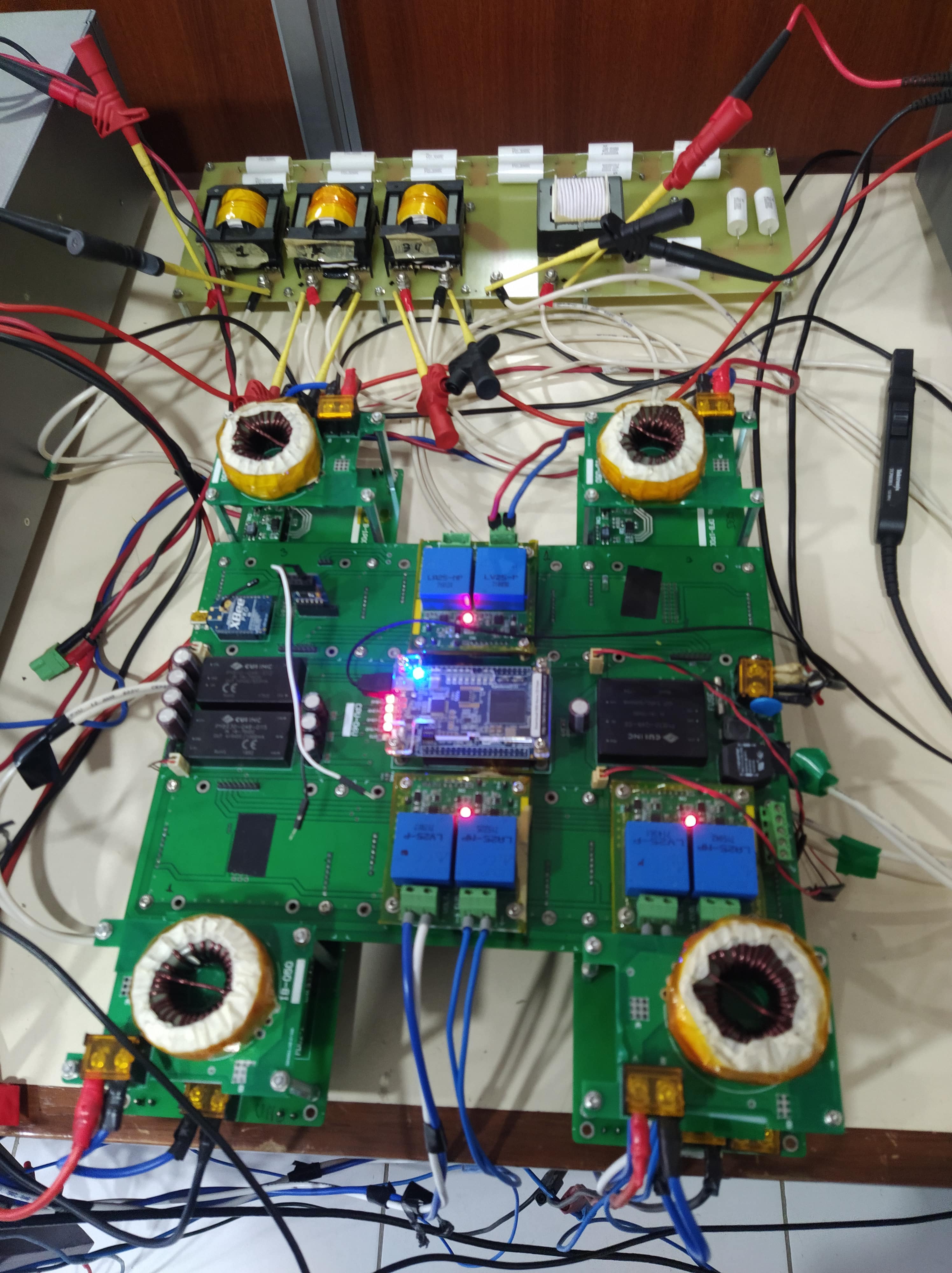

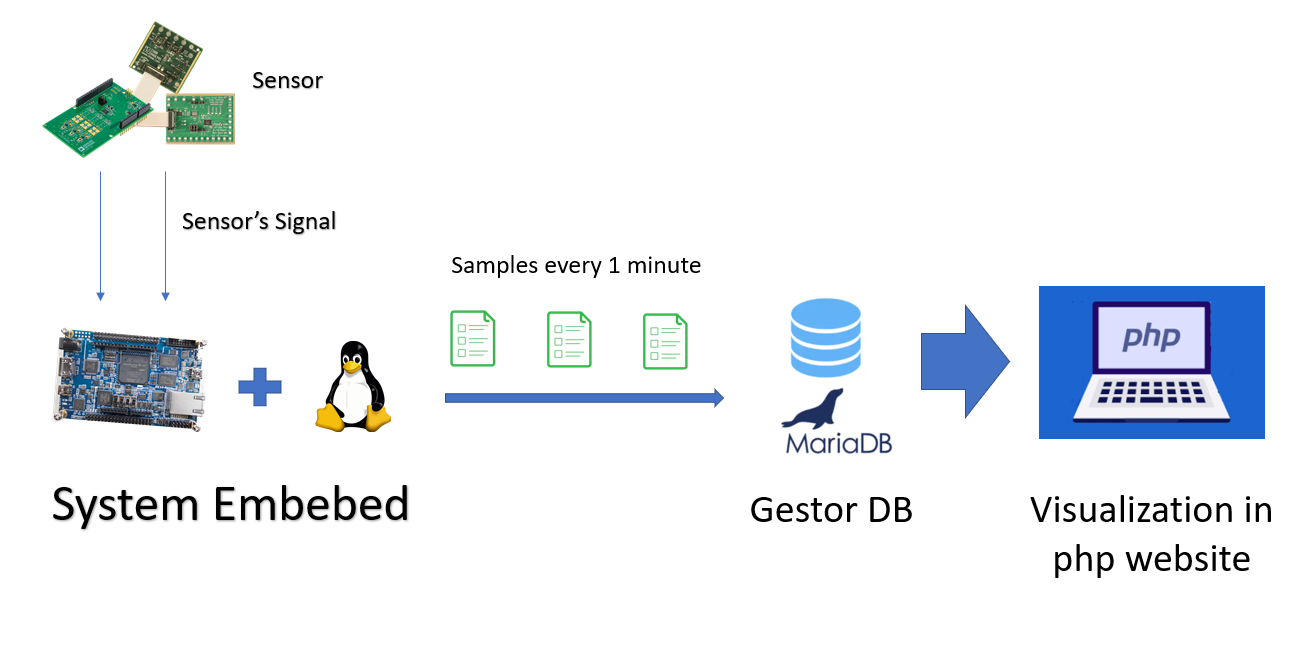

The prototype consists of developing a solution adaptable to any converter topology capable of managing the power flow and allowing data to be viewed in the cloud. This will have a Linux system integrated in the hardware that monitors the signals in real-time and sends them to the cloud (Microsoft Azure server) so that they can later be seen by the user, it will also be able to alert the user of problems, the user will be able to access to it remotely using an SSH server installed on the board to suspend or restart the operation of the converter. All of these algorithms can be implemented on the same DE10-Nano Cyclone V SoC FPGA board. In addition, Analog Devices plug-in cards (DC1338B, DC1012A-A, and CN0397) are used to monitor the main electrical variables of the drive. Therefore, this prototype aims to validate the controller and a system capable of monitoring the electrical signals from the converter, which can then be used for global energy monitoring over a city.

6. EXPECTED RESULTS:

The changes that are planned to be achieved with the execution of the project are: mainly to improve the efficiency of a process that requires power converters that use renewable energies such as solar panels or wind turbines, making the process measurable, controlled, and improved, and also obtain capabilities for the control remote that will save time and money. In the medium and long term, observe the economic benefit that the use of renewable energies brings instead of conventional ones and care for the environment by reducing gas emissions that accentuate global warming, allowing public access to green energies.

The main contribution is to contribute to the integration of clean energy with the grid, in a safe way for the user and can have enough confidence in it, in addition to growing the industry through the innovation presented in this project.

4. Design Introduction

The design consists of connecting a single-stage bidirectional DABRS converter to the Azure server, where the DE10 nano controls the modulation and the proposed control strategy described in VHDL[1], and sends the information to the cloud.

Note in the image the converter uses a DE0 nano, which is easily replaced by the DE10 nano and since it has an ARM it can embed a Linux system to send the data sensed through the HPS to the server. So, it is clear that the purpose of the project is to remotely access the information of the converter regardless of the topology and control the power flow of various nodes in the cloud.

The HPS was used to connect the hardware with the software, it is an advantage of using an FPGA compared to other devices. Likewise, in power electronics, due to the amount of PWM signals, FPGAs are used.

5. Functional description and implementation

First, the modulation and control strategy for the converter to be used is described in VHDL. And previously it is simulated in PSIM.

.png)

PSIM can be used as the power electronics simulator via Simcoupler and work in the Matlab environment using DSPBuilder's HIL. However, the data generated by performing a HIL cannot be sent out by a GPIO.

Therefore, it works with the presented hardware, and the control board for the De10nano in Altium is going to be corrected.

Then, through the use of ROM memories, electrical signals are simulated, which are displayed by means of graphs on a server in Azure. To do this, an HPS with multiple inputs of the electrical signals sensed is first designed. Which are the voltages of the three-phase grid, the currents of the three-phase grid, the current and voltage of the battery, the current and voltage of the solar panel, and finally the phase shift between the ports.

Once the project is compiled using bash, the header file is created, which will be the following:

#!/bin/sh

sopc-create-header-files \

"./cpu.sopcinfo" \

--single hps_0.h \

--module hps_0

Then a small script is programmed in c and the file is generated for Linux by means of make by console.

.png)

In Linux on the FPGA, the file that we have sent by scp is executed and with crontab the text file with the data is sent to the server.

.png)

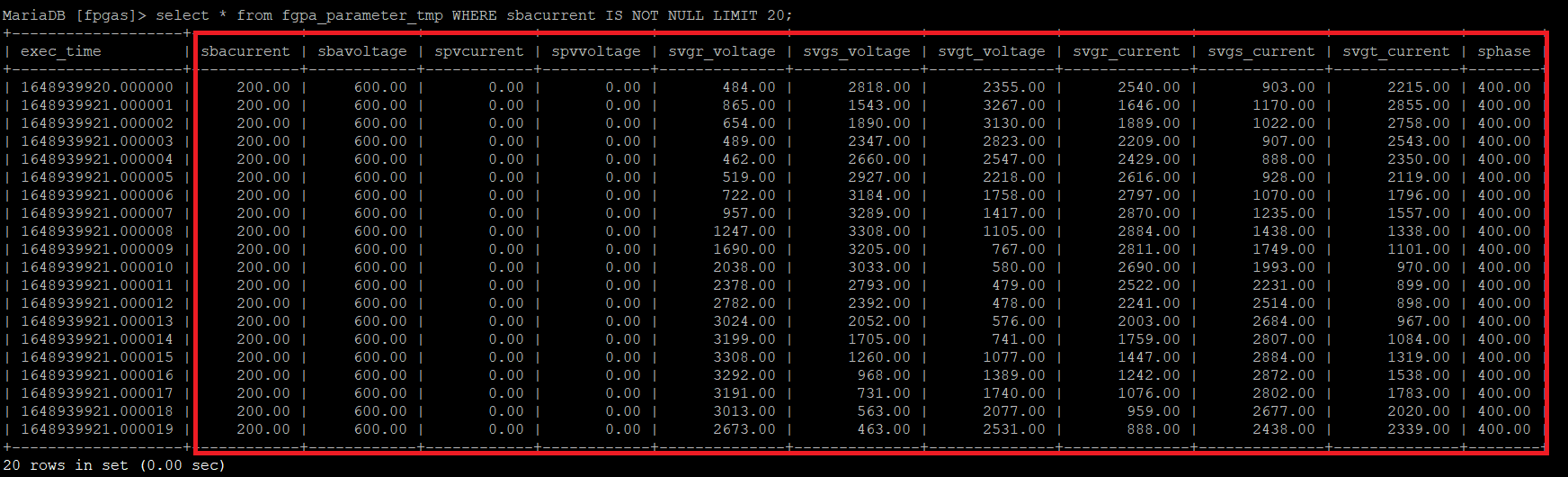

The FPGA obtains the values from the sensors for one minute and then these are deposited in the Azure server, which is loaded into a MariaDB database. This way of treating the data gives us the flexibility to do massive data loading when If you work in more complex and larger networks, you can take advantage of the management of tables in columnstore, which uses a massively parallel distributed data architecture in which you can do fast operations with large amounts of data.

.png)

6. Performance metrics, performance to expectation

The FPGA is highly parallelizable this helps in signal processing and also to generate

control systems in these, in addition to SOC-type FPGAs, have ARM in which an S.O. can be embedded, which can be easily connected to local or remote servers through Ethernet interfaces.

7. Sustainability results, resource savings achieved

''''

In summary, signal readings are obtained through sensors which are read by the FPGA and the OS, these generate packets every minute which are transported to the server which has an integrated MariaDB for data storage and web design in PHP for the visualization of these.

8. Conclusion

Regardless of converter topology and even focus area, any physical signal can be visualized in the cloud using HPS and the FPGA.

FPGA has multiple advantages in the computational field due to the parallel processing as it was done with the HPS with the information from the sensors.

[1] Daniel Chavez and Damian Sal y Rosas, “Single-Stage Isolated and Bidirectional Three-Phase Series-Resonant AC-DC Converter: Modulation and Control”, IEEE TRANSACTIONS ON POWER ELECTRONICS, in pres, 2022.

[2] https://mariadb.com/kb/en/columnstore-architectural-overview/

2 Comments

Please login to post a comment.

keith woollvin

Hi Daniel, I enjoyed reviewing your project - congratulations on demonstrating such a complex system. I see you haven't quantified any efficiency expectations or savings - can the you comment on how sustainability results for this project could be quantified?