IOT system for mango preservation using Microsoft Azure and FPGAs.

Demo Video

Project Proposal

1. High-level project introduction and performance expectation

In Peru, mango is the 4th most exported fruit, representing 0.41% of the agricultural GDP and the livelihood of 6 thousand farmers in our country. The largest producers of this fruit are small farmers with 80% of production compared to large farmers (5% of mango production). It means that most of the fruit produced does not have a high-quality infrastructure for the conservation and transport of the fruit, which involves shocks in the transfer, and poor climate control of the container, among others. It causes damage to several fruits that reach bad conditions and are finally discarded, even before being marketed, resulting in fruit waste. For these reasons, our main objective is to improve the mango preservation system to be able to monitor the ripening state and control its speed, avoiding a massive waste of food.

It is necessary to have a system that is capable of controlling and monitoring the different parameters for the optimal conservation of mango that integrates Microsoft Azure services and uses analog devices, such as CN0395 Volatile Organic Compound Detector for Indoor Air Quality Measurement to recollect information. An Intel FPGA allows us to monitor mango's different parameters using Analog Devices products to determine its ripeness state, and Microsoft Azure services allow us to monitor them. It permits us to act if something happens during transport or conservation to preserve fruits whenever is possible.

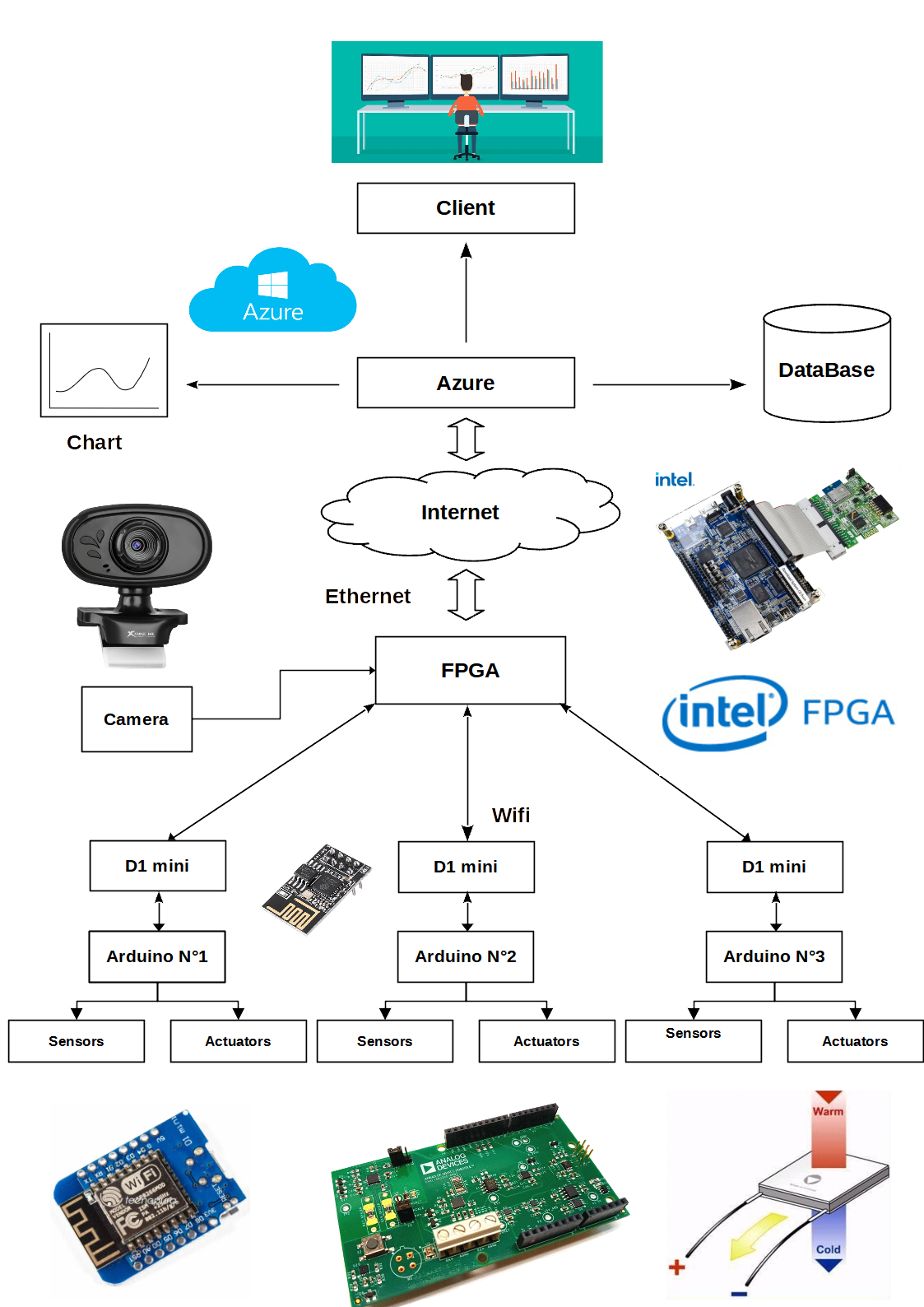

The system design also includes a camera, which detects color variations to avoid over-ripening. First, Arduino will acquire data, and send it to a web server to be received by the FPGA via Wifi. The communication with the cloud will be bidirectional when Azure communicates with the DE10-Nano development board, which will receive the data for processing and decision-making. Once we have the processed data, the FPGA will communicate with the cloud to implement a system to monitor data; and parallelly drive our actuators, avoiding the carbon monoxide in the medium to reduce its ripening speed and controlling the temperature using Peltier cells. We emphasize that communication will be established with the cloud using the ESP-WROOM-02 module. The project contemplates the possibility of taking advantage of the parallel processing of the FPGA by using more than one data collection point operating simultaneously, controlling the actuators, and performing the image processing to detect color variations, thus taking advantage of the parallel-processing capacity of DE10-Nano.

For our project, Intel offered us a powerful and interactive development environment (Quartus Prime Lite), which integrates other tools such as Eclipse to exploit our capabilities to the maximum and synthesize this project. Also, we use Microsoft Azure Portal and Azure IoT Central to visualize it online.

Thinking about the scalability of our project, we focused the application on small and medium producers, which represent 90% of mango producers, seeking that with the help of our project food waste is reduced, in this case, mango. Similarly, the project will benefit mango exports, promoting technological innovation and its results reflected in the quality of the fruit. Finally, we seek to make the project scalable by applying it to different climacteric fruits.

2. Block Diagram

3. Expected sustainability results, projected resource savings

The conservation of the fruit depends on certain factors, which, if controlled, allow prolonging the ripening time of the fruit.

This system allows the control of various devices which will be assigned to a container for data collection of relative humidity, maintain the temperature in a good range, the concentration of the carbon concentration should be as low as possible on ppm, the control of these parameters will serve to prolong the ripening of mango.

The implemented system will allow farmers and people in charge of planting, harvesting, and transporting the fruit to make better use of their resources.

The new technology developed by Microsoft to deploy edge services on the Azure cloud makes the IoT development with FPGA a new world to explore and in this way, the edge devices will increase by using one FPGA to receive data from a group of microcontrollers such as Arduino and ESP acting as little server nodes.

4. Design Introduction

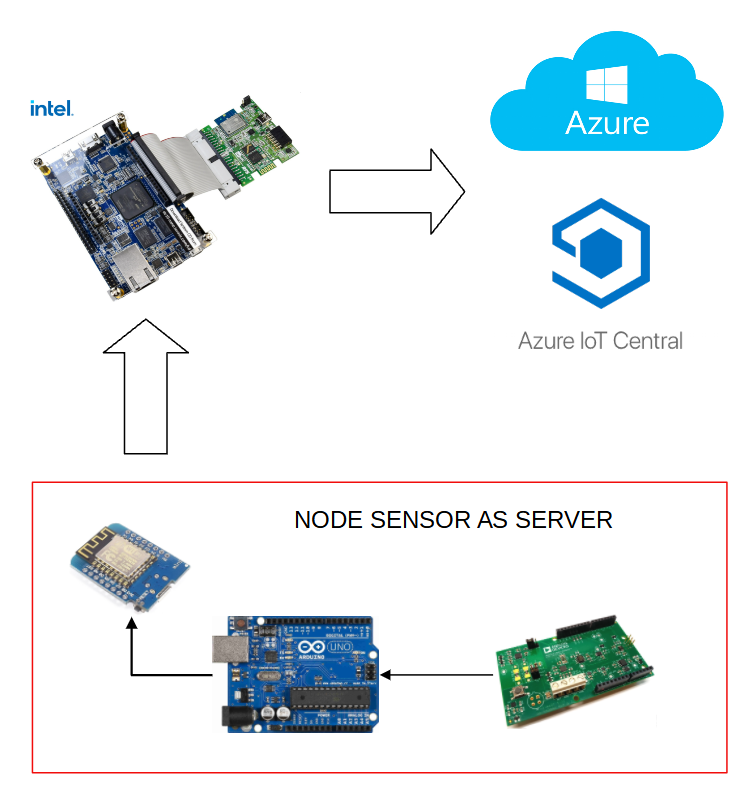

The proposed system establishes some Arduinos as initial sensing nodes that help us to acquire data such as humidity, temperature, and carbon concentration in the environment. These parameters allow us to diagnose if the fruit in question has the right conditions for its conservation. The computational performance offered by these microcontrollers platforms is not very convenient to connect them directly to the cloud. They also generate higher data traffic when sending data from each small server to Azure (so it would be more expensive due to higher consumption resources). That is why we concentrate all data in an FPGA that can process the data and then send it to the cloud service so that there is less data traffic and better management of the Azure edge service. That is why it is convenient to carry out a pre-processing with the FPGA to analyze the data from several nodes and combine them to send a single communication frame to the cloud, taking advantage of its flexibility in specific applications. The FPGA carries out the actions of forwarding data from the sensing nodes to the cloud for its monitoring and control by the user.

5. Functional description and implementation

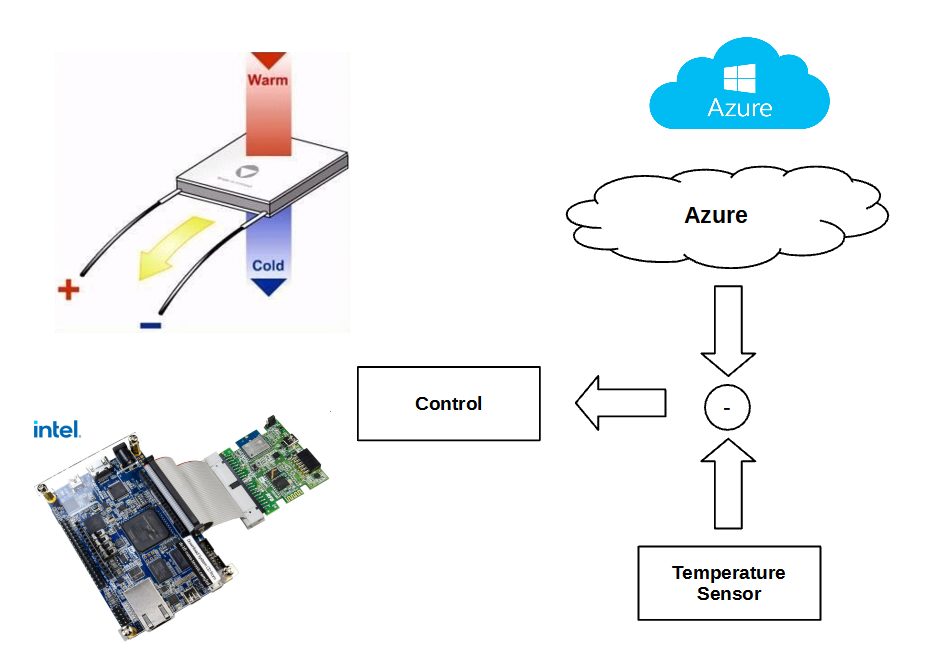

Our design implements a simple temperature control system with a Peltier cell as an actuator, whose set point is indicated by the Azure cloud telemetry services.

Additionally, to provide the user with the available data, we have a network of servers distributed in a region, which is in charge of measuring through different sensors, such as temperature, position, humidity, and carbon concentration. It allows us to have constant monitoring for the parameters of our agricultural products.

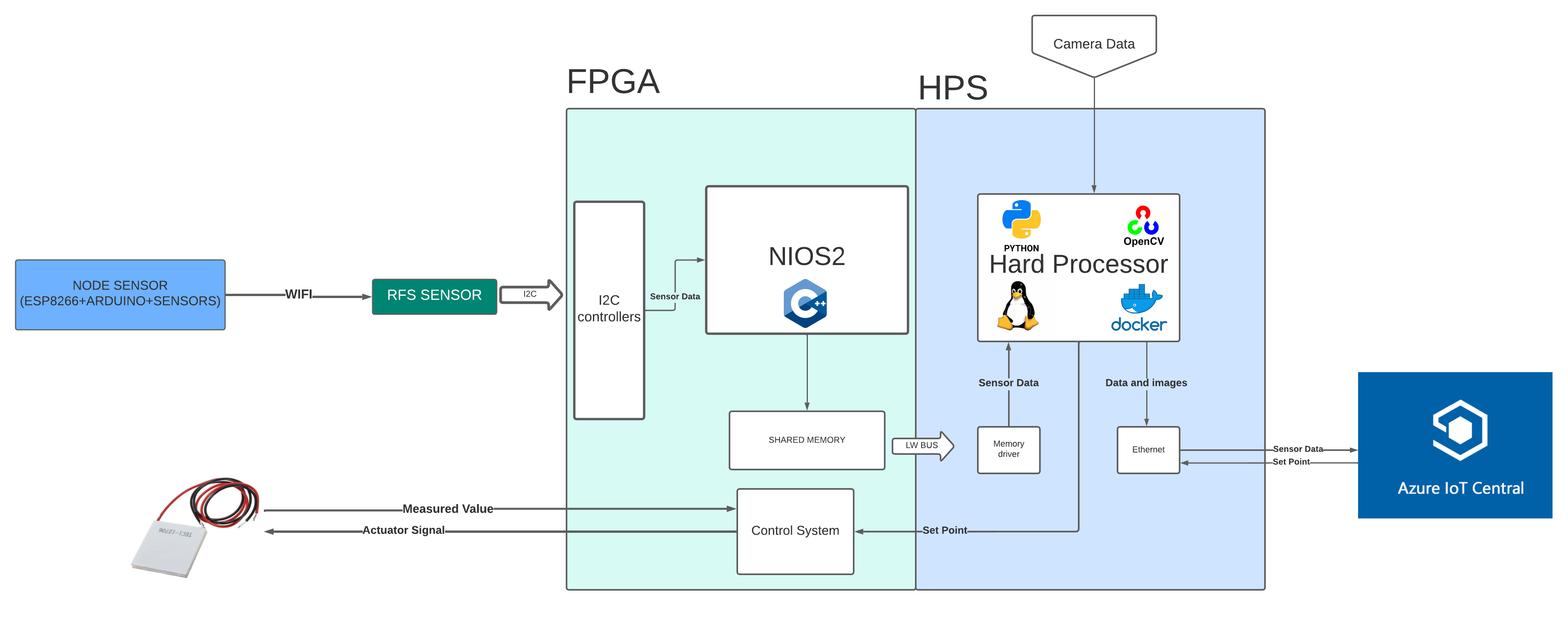

The Hard Processor System (HPS) allows us a high-level development environment, which we use to perform the image processing through OpenCV and to perform the color gradient of the fruits as an additional indicator of the performance of the de10 nano board.

6. Performance metrics, performance to expectation

The design aims to reach complete independent processing of the three tasks and communicate all the running time with the Azure cloud. For this reason, we need to have good internet connectivity, thereby, the FPGA uses an ethernet connection, and the node sensors are limited to sending the data via Wi-Fi.

The FPGA uses its natural frequency clock of 50MHz. The de10 nano development board allows us to create software and hardware applications simultaneously, allowing us to develop specific algorithms (like the edge detector or the PID controller) directly in hardware and software applications in python to do data sending to the cloud and management of data.

Implementing the three processes on a single board makes the design more portable and suitable as an IoT solution for monitoring agricultural products or sensing products in general.

7. Sustainability results, resource savings achieved

The architecture developed inside the DE10 NANO board looks like the following image:

Where we can do the 3 processes on the same board.

The workflow of the system can be represented in the following steps:

Sensor Process:

-

The DE10 Nano sends a request to each server from the sensor nodes, they are in the same local area network but with different IP addresses.

-

The data is written on a shared memory, which can be read by the Hard Processor by the operating system place reserved for the physical memory.

-

The data is managed with Python to send it to the Azure cloud service.

-

The data is visualized on the IoT Central service.

Control Process:

-

The setpoint is managed by the Azure cloud service and received by the Hard processor

-

The hard processor sends the setpoint value to the FPGA

-

A simple PID controller implemented with VHDL language gets the data and sends a Process variable to an actuator.

Camera Process:

-

The camera sends the raw data to the HPS.

-

The data is processed with OpenCV and Python for color detection of the sensed product, then the image is sent to the Azure Cloud.

8. Conclusion

● SoC FPGA allows us to implement high computational systems quickly and easily through the integration of hardware and software, allowing the development of new solutions.

● The high compatibility in the development of Intel FPGA with Azure cloud allows the rapid integration of new IoT solutions for sustainability in agriculture or any production environment.

● The high precision of the sensors provided by Analog Devices allows the easy integration of solutions in industrial and unfriendly environments.

1 Comments

Please login to post a comment.

keith woollvin

Hi guys, I enjoyed you presentation and you seem very talented engineers. I think it would be great if you can think a little more about the sustainability goal of the project. Do we know what % of fruit has to be discarded today? Were you able show that this system could improve the loss? It would be great to see actual the telemetry date being gathered and sent.