PR002 » PickingRobot

针对羽毛球捡球机的设计与实现面临找球难和捡球难等问题,我们团队设计了一款用于羽毛球捡拾的智能捡球机器人。该捡球机器人利用摄像头辅助激光雷达实现羽毛球的定位,利用自主设计的捡球装置实现了羽毛球的无损伤拾取

purpose:

In order to enable the ball picking machine to quickly identify and locate badminton, we hope to use the powerful parallel computing power of the FPGA to quickly process the image information, so that the ball picking machine can obtain the badminton position information in real time and achieve the goal of fast ball picking.

Application:

In badminton training, the picking-up is still done by people. In the training of high intensity and long duration, frequent picking movement will accelerate the physical exertion of the practitioner, thereby reducing the training effect. This topic attempts to design a ball-carrying machine that can automatically pick up badminton in the badminton court through artificial intelligence-related technology to replace the trainer to pick up the ball.

Target users:

The shuttlecock-picking robot designed by this subject is mainly used for on-site badminton training. After the prototype is developed, it can be used as a sports equipment for badminton. At present, there is almost no automatic shuttlecock-picking on the market. The robot used for badminton training will enhance the badminton training effect and increase the interest of badminton training. It can also provide theoretical research for other robots. Reference and practical experience.

This figure shows the running process of the intelligent shuttlecock-picking robot system. At work, the picking robot uses the laser scanning sensor and camera data to achieve fast positioning and accurate identification of the on-site badminton. On this basis, the SoC sends the badminton information to the action execution part according to the strategy of the nearest distance to finally complete the ball-picking action.

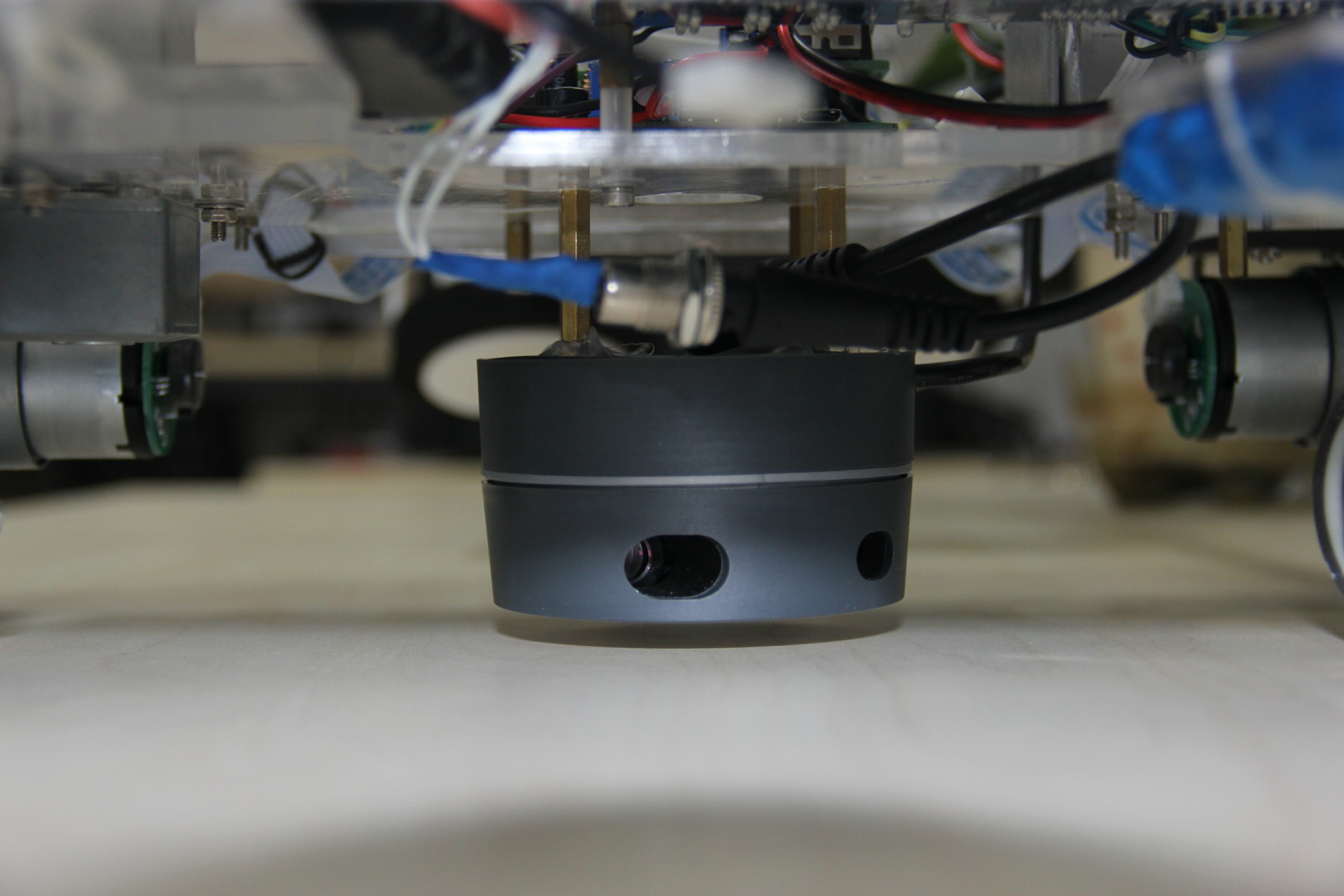

The positioning part is completed by the camera and the laser radar. The laser radar completes the badminton rough recognition and gives the coordinate information of these meaning badminton objects. The camera judges these suspected badminton objects and saves the real badminton coordinates. In this way, the identification and positioning of the badminton can be achieved by using a laser radar and a camera. This alternate operation of the lidar and camera does not require high performance of the processor, and it also helps to reduce system power consumption.

The control section consists of an FPGA, a Nidec motor, an encoder, a position sensor and a photoelectric sensor. As the core of the control part, FPGA obtains the angle and distance information of badminton from SoC, combines the encoder data, and realizes the automatic pick upf the picking-up robot and the automatic homing function of the ball frame through the control of the motor. The photoelectric sensor determines whether the ball is successful by detecting whether there is a goal in the ball frame. At the same time, the photoelectric sensor can also detect whether the ball frame is in the full state.

The SoC design solution can be used to facilitate developers. The positioning algorithm and the motion control algorithm program are finally run on the DE1-SoC development board. The program verified on the desktop Linux system will eventually need to be ported to the DE1-SoC. Utilizing the powerful parallel computing processing capability of FPGA, FPGA is used as a large computational data processing platform, and the time-consuming part of the image recognition algorithm is transplanted into the FPGA; Utilize the powerful interface management capabilities of Linux to port the rest of the program to embedded Linux. In this way, according to the advantages of arm and FPGA, the algorithm program is transplanted to arm and FPGA respectively, so that the embedded system runs in the direction of low delay and high reliability.

The total program consists of two parts, namely the badminton positioning and motion control program. The two are communicated by serial port. The program flow is shown in the figure. The badminton positioning has two threads, the main thread is a lidar rough recognition program and a data fusion program, and the receiving thread is a badminton recognition program.

As can be seen from the flow chart, two threads are opened in the badminton locator. At work, the lidar rough recognition thread has been detecting the scan, scanning the thread that wakes up the badminton recognition program after badminton-like objects. The processed path information is finally sent to the FPGA through the serial port.

The system uses the data fusion of lidar and camera to complete the acquisition of badminton position information, and can process the acquired angle and distance information through the single-chip computer, adjust the control robot in real time, realize automatic ball finding, picking-up and ball full auto-homing function. The robot moves stably and efficiently

1.Picking success rate

The shuttlecock-picking robot has the same success rate for badminton picking in different postures. The research team analyzed the badminton posture dropped on the ground and classified it into four categories, namely, the feather facing ball machine (referred to as feathers) and the ball head. Right on the ball machine (referred to as the ball head is right), the badminton sideways toward the ball machine (referred to as the side), badminton standing on the ground (referred to as standing). The badminton attempt for each of the above gestures is picked up 50 times, and the number of successful successes is recorded, and the success rate of the croquet for each posture is divided by the number of successes divided by the number of picks. The success rate of the Picking-up reflects the excellent degree of the Picking-up device and the Picking-up strategy. This parameter is currently in the optimization stage, and the specific values will be given in the subsequent demonstrations.

2.Picking speed

The speed of picking up the ball refers to the number of times (the number) the robot successfully picks up the badminton. The value varies with the badminton. The speed of the picking represents the overall performance of the robot. Among the factors supporting the performance parameters of the ball, the target recognition has an important proportion. The part of the subject that involves large computational complexity of the image is processed in the FPGA. Compared to the traditional arm processor, the computational process is much less time consuming. The speed of the ball is still in the optimization stage, and the specific value will be given in the subsequent display.

The hardware connection is as shown in the figure. The FPGA is connected to a laser radar for acquiring badminton position information and a camera for acquiring image information. The driving board is connected with a photoelectric sensor for detecting a goal, a lifting mechanism limit sensor, a displacement motor Hall sensor, and a pendulum. The blast motor of the positive ball, the flywheel motor for the picking-up, the lifting motor of the lifting and lowering ball device, and the displacement motor responsible for the movement of the picking robot.

According to the software processing flow, the software of the intelligent shuttlecock-picking machine is divided into two parts according to the function classification: path planning and motion control, as shown in Figur. At the SoC, the target recognition program completes the identification of the badminton in the badminton court; the target ranging program uses the data returned by the laser radar to perform rough detection of the badminton and obtain the coordinates of the suspected badminton object; the data fusion program completes extracted and merged the of informations target identification and target ranging. Finally the coordinate information of the badminton is given, and then the path planning is completed; the pickup control program gives the corresponding motion instruction according to the coordinate information of the badminton, and the action execution end only needs to act according to the specific command.